PP plastics panel boxes

For the transport of professional and expensive equipment,settling for standard packaging is an untenable risk. Polypropylene panel boxes represent the evolution of protective logistics

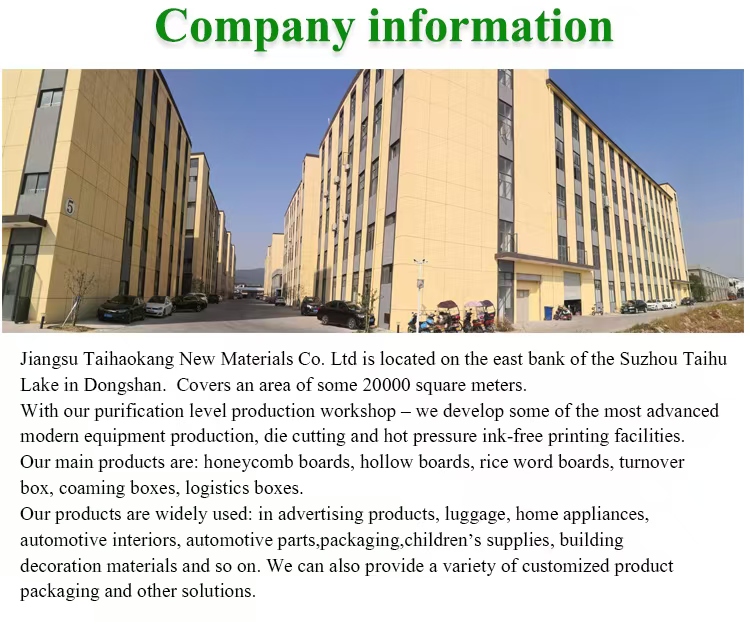

Jiangsu Taihaokang New Material Co., Ltd.

In the world of professional and high-value equipment transport—from sensitive medical devices and aerospace components to electronic instrumentation

and film production gear—the stakes are incredibly high.

A single instance of impact, vibration, or environmental contamination during transit can result in catastrophic financial loss and operational downtime. In

this critical chain, protective transport packaging is not merely a box; it is an essential insurance policy.

Among the solutions available, the polypropylene panel box has emerged as the premier choice, offering a unmatched blend of protection, efficiency, and

intelligence.

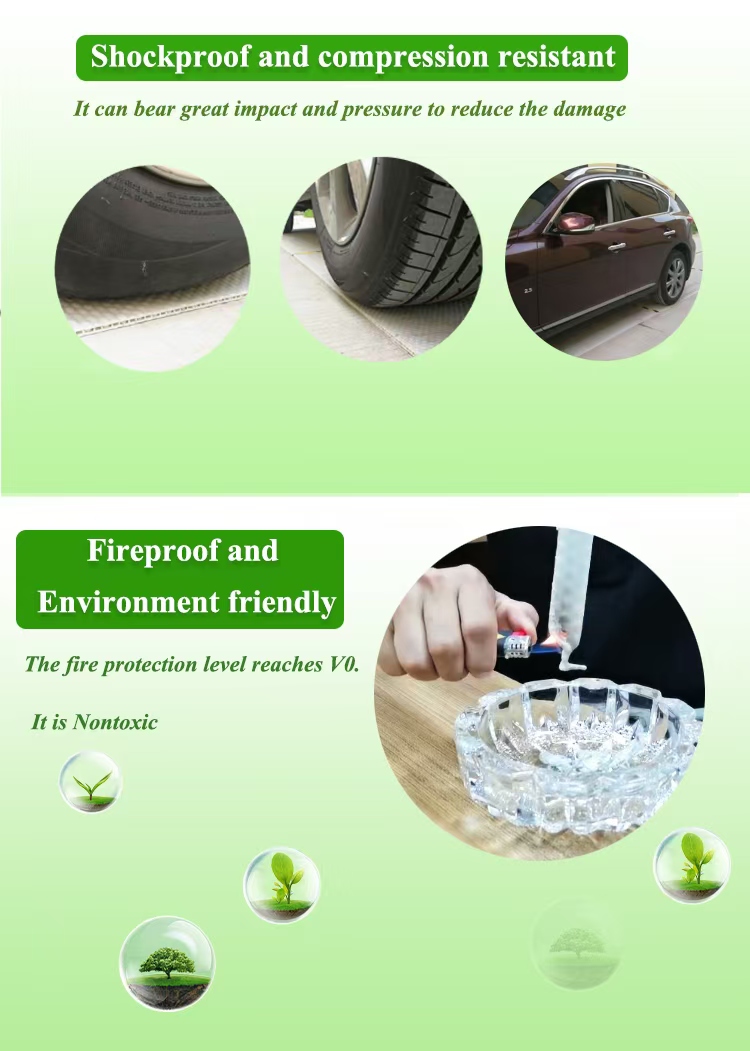

1. Unrivaled Protection and Durability

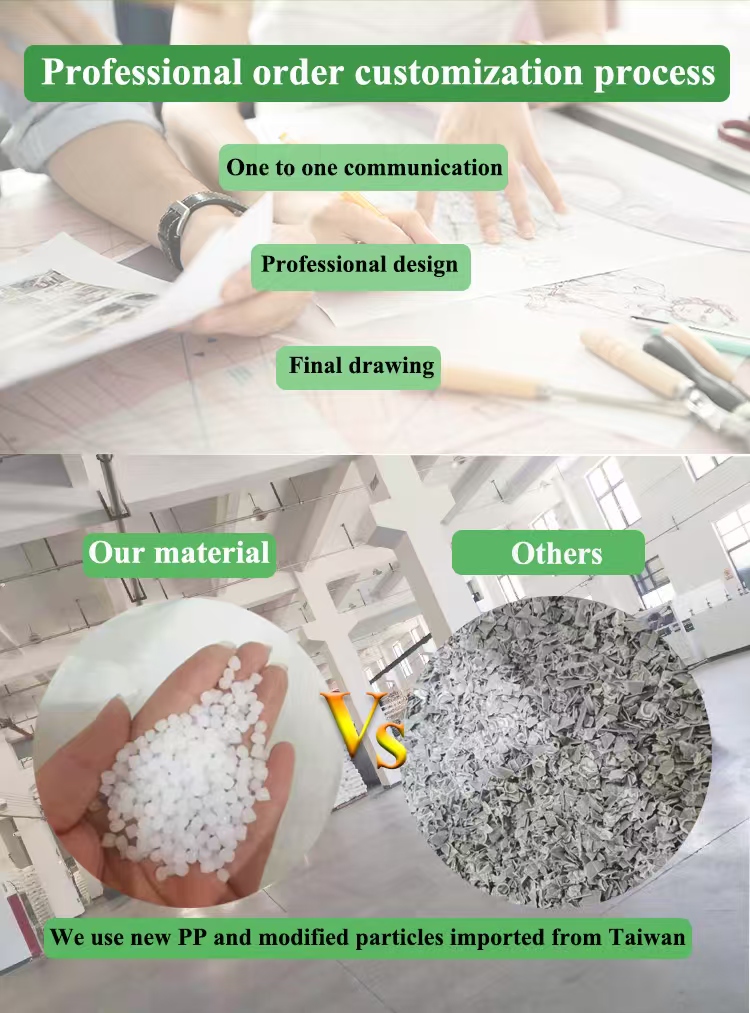

Polypropylene(PP) panel boxes are engineered for resilience. The material itself is inherently impact-resistant, moisture-resistant, and chemically inert, safeguarding contents from shocks, humidity, and corrosive substances. Unlike cardboard, PP does not absorb water, ensuring strength is maintained in diverse climates. The design—typically featuring a separate base, lid, and interlocking panels—creates a rigid, full-perimeter structure that acts like a protective cage. This design excels in stacking strength, allowing multiple loaded boxes to be safely stacked, maximizing warehouse and transport space without compromising the safety of the bottom unit.

2. Operational Efficiency and Cost-Effectiveness

Beyond initial protection,PP panel boxes offer profound logistical advantages. Their collapsible design is a game-changer. When empty, the panels can be disassembled and stored or returned flat, slashing storage space and return freight costs by up to 80% compared to rigid containers. This makes them ideal for closed-loop logistics systems. Furthermore, their durability ensures a multi-year lifespan, surviving hundreds of trips where cardboard would be single-use. This translates to a lower total cost of ownership , eliminating the recurring expense of purchasing disposable packaging and reducing waste disposal fees.

3. Enhanced Security and Customization

Security is paramount for expensive assets.PP panel boxes can be fitted with robust locking mechanisms and seal points, deterring tampering and providing clear evidence of unauthorized access. The smooth surfaces are also perfect for permanent branding or asset tracking labels, improving inventory management. For specialized equipment, the interior can be easily customized with modular foam inserts, CNC-cut to cradle each component securely, eliminating internal movement—the primary cause of in-transit damage.

4. Sustainability and Professional Image

In today's eco-conscious market,sustainability is non-negotiable. Polypropylene is a fully recyclable material at the end of its long service life. By enabling a reusable, circular economy model, these boxes dramatically reduce cardboard waste, carbon footprint from constant manufacturing, and overall environmental impact. Additionally, their robust and clean appearance projects a professional, high-quality image for your brand, signaling to clients that you value and protect your products—and theirs.

For the transport of professional and expensive equipment,settling for standard packaging is an untenable risk.sustainable business practices. They are not just containers; they are a strategic asset in the supply chain, ensuring that valuable cargo arrives safely, efficiently, and ready for action. Investing in PP panel box systems is ultimately an investment in reliability, reputation, and the bottom line